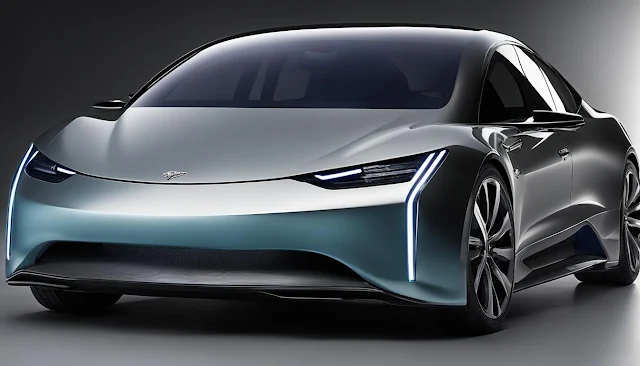

Unleashing Power: The 500 hp Electric Motor for Car Explained

The 500 hp electric motor for car is a high-performance, efficient electric motor that delivers exceptional power and torque. It is designed to meet the demands of modern-day vehicles, providing a sustainable and eco-friendly alternative to traditional combustion engines. This electric motor is the driving force behind many electric vehicles, providing reliable and efficient performance on the road.

With its ability to generate 500 horsepower, the high-power electric motor for vehicle represents a significant breakthrough in automotive technology. It is an efficient electric motor for automotive applications, providing a clean and sustainable source of energy. The 500 hp electric motor for car is capable of propelling vehicles to high speeds, making it an ideal choice for high-performance electric vehicles.

The efficient electric motor for automotive boasts numerous benefits over traditional combustion engines. Not only is it more energy-efficient, but it also produces fewer emissions, making it a more environmentally friendly option. This electric motor is also quieter and requires less maintenance, contributing to a more enjoyable driving experience.

Overall, the 500 hp electric motor for car represents a significant advancement in automotive technology. With its impressive power and efficiency, it is quickly becoming a preferred choice for high-performance electric vehicles. As the demand for eco-friendly transportation options continues to grow, this efficient electric motor for automotive applications is set to become even more popular in the years to come.

How Does a High-Power Electric Motor Work?

A high-power electric motor for a vehicle is designed to provide efficient performance and deliver 500 horsepower to meet the demands of high-speed electric vehicles. The motor typically consists of several key components, including a rotor, stator, and power electronics.

The rotor is the rotating part of the motor that generates the motor's output power. It is typically made up of a series of conducting bars that are connected to form a loop. The stator is the stationary part of the motor that surrounds the rotor and houses the motor's windings. The windings are typically made of copper wire and carry an electric current that produces a magnetic field.

How Does the Electric Motor Generate Power?

When an electric current is applied to the windings of the stator, it creates a magnetic field that rotates around the rotor. This magnetic field induces an electric current in the rotor bars, which in turn creates a magnetic field around the rotor. The interaction of these magnetic fields generates torque, which drives the rotation of the motor.

The power electronics are responsible for controlling the motor's operation by managing the flow of current to the windings. This helps to ensure that the motor operates efficiently and delivers the required power output.

What Makes a High-Power Electric Motor Efficient?

A high-power electric motor is designed to be as efficient as possible, which means it converts as much electrical energy as possible into mechanical energy. This is achieved through careful design of the motor's components and the use of advanced materials.

For example, the windings of the motor may be made of high-conductivity copper wire to minimize electrical losses. The rotor and stator may be constructed from materials such as aluminum, which are lightweight and have good electrical and thermal conductivity.

Overall, the key to the efficiency of a high-power electric motor is the optimization of its design and components to minimize energy losses and maximize power output.

In summary, a high-power electric motor for a vehicle generates power by creating a magnetic field around a rotor and inducing an electric current in the rotor bars. The power electronics control the motor's operation to ensure it operates efficiently and delivers the required power output. The motor's efficiency is optimized through careful design of its components and the use of advanced materials.

Design and Construction of Electric Motors for Cars

Developing car electric motor with high performance requires a carefully designed construction to achieve powerful and efficient operation. Engineers consider many factors when designing electric motors for automotive applications, including the size and weight of the motor, materials used, and cooling systems.

High-speed electric vehicles require motors that can efficiently convert electrical energy into mechanical energy without overheating or wearing out quickly. High-performance electric motors for electric vehicles must also be lightweight to reduce the overall weight of the vehicle, which enhances energy efficiency and range.

Materials

The materials used in the construction of electric motors can significantly impact their performance and durability. Modern electric motors are usually constructed with copper wire windings that sit within the magnetic field produced by permanent magnets. The magnets can be made of various materials such as neodymium, iron, and boron, that have high magnetic strength and stability.

Other materials used in the construction of electric motors include cast aluminum rotors and casings, which are lightweight and have excellent thermal conductivity, allowing for efficient heat dissipation. Ceramic components are also used in motors as they have high heat resistance, good electrical insulation, and are wear-resistant.

Cooling Systems

The cooling system is another important consideration in designing electric motors for high-speed electric vehicles. The high power output of these motors generates significant heat that needs to be dissipated efficiently to prevent overheating and potential motor failure.

There are several cooling methods available, including air and liquid cooling. Air cooling relies on a fan that blows air over the motor's casing to transfer heat away from the motor. Liquid cooling, on the other hand, uses a coolant that is circulated through channels within the motor's casing to absorb and transfer heat away from the motor.

Efficiency

Efficiency is a crucial factor in the design of electric motors for automotive applications. Inefficient motors waste energy and generate more heat, which can lead to motor failure. Electric motors for high-speed electric vehicles must have high power density and efficiency to deliver the necessary power while minimizing heat generation and energy loss.

Efficiency is affected by many factors, including the motor's design, size, materials, and cooling system. Motors with higher efficiency have lower operating costs, lower emissions, and require less maintenance, making them ideal for automotive applications.

Power and Torque: The Driving Force of Electric Motors

When it comes to electric motors for cars, power and torque are the two essential factors that determine their performance and driving characteristics. A powerful electric motor for cars features a high-horsepower rating, while a high-torque electric motor for automotive applications delivers exceptional acceleration and pulling power.

The 500 hp electric motor for cars is a prime example of a powerful electric motor engineered to meet the demands of high-performance electric vehicles. With an electric motor with 500 horsepower, drivers can experience unmatched speed and acceleration, making it an ideal choice for sports cars, race cars, and other high-speed applications.

Power and Torque: Two Sides of the Same Coin

In electric motors, power and torque are closely related and can be thought of as two sides of the same coin. Power is the rate at which work is done, while torque is the force that produces rotational motion. The higher the power output of an electric motor, the faster it can propel a vehicle. Likewise, the higher the torque output of an electric motor, the greater the force it can exert to accelerate or pull heavy loads.

To understand how power and torque work together, consider the example of a car accelerating from a standstill. The electric motor must overcome the inertia of the car and generate enough torque to move it forward. As the car gains speed, the electric motor must continue to produce enough torque to maintain its momentum and overcome frictional forces. As the electric motor's torque output decreases at higher speeds, its power output must increase to maintain the same level of acceleration.

The Role of Gear Ratios in Electric Motor Performance

Another critical factor that affects the performance of electric motors for cars is the gear ratio. The gear ratio determines the relationship between the speed and torque of the electric motor's output shaft. A high gear ratio provides high torque output but low speed, while a low gear ratio delivers high speed but low torque output.

To optimize the performance of an electric motor for a specific application, engineers must carefully select the gear ratio to ensure that it delivers the necessary power and torque output. This is especially important for high-performance electric vehicles that require both high speed and high acceleration capabilities.

Overall, the power and torque output of an electric motor are critical factors that determine its performance and suitability for different automotive applications. A powerful and high-torque electric motor with 500 horsepower can deliver impressive acceleration and speed, making it an ideal choice for sports cars and other high-performance vehicles.

Electric Motors for Sports Cars: Unleashing Performance

The rise of electric sports cars has brought about a new era of high-performance vehicles. With the 500 hp electric motor for cars, these vehicles offer exceptional acceleration, speed and handling, all while producing zero emissions.

One of the main advantages of electric motors for electric sports cars is the instant torque they provide. Unlike traditional internal combustion engines, electric motors deliver full torque from the moment the accelerator is pressed, resulting in lightning-fast acceleration. This is particularly beneficial for sports cars, where quick acceleration and precise handling are essential for optimal performance.

Another advantage of electric motors for electric sports cars is their efficiency. Electric motors are more energy-efficient than internal combustion engines, resulting in lower operating costs and reduced environmental impact. In addition, electric motors require less maintenance since they have fewer moving parts than traditional engines. This means less time spent on maintenance and more time spent on the road.

The Future of Electric Motors in Sports Cars

The future of high-performance electric sports cars looks promising, as advancements in electric motor technology promise to improve upon the already impressive performance of these vehicles.

One area of research is the development of electric motors with even higher power outputs. By increasing the power of electric motors, sports car manufacturers can deliver even greater performance and acceleration. Additionally, advancements in battery technology will enable electric sports cars to travel greater distances on a single charge, making them more versatile and convenient for everyday use.

Overall, electric motors for electric sports cars offer a new level of performance, efficiency, and sustainability. With further research and development, these vehicles are poised to become the future of high-performance, environmentally-friendly transportation.

Advantages of Electric Motors in Automotive Applications

Electric motors are rapidly gaining popularity in the automotive industry due to their remarkable energy efficiency and low environmental impact. They are now being used extensively in high-performance electric vehicles thanks to their ability to produce high power output with minimal energy consumption. Below are some of the advantages of using efficient electric motors in automotive applications:

Reduced Emissions

One of the most significant benefits of electric motors over traditional internal combustion engines is their low emissions. Electric motors produce no greenhouse gases and do not release pollutants such as nitrogen oxides, which are harmful to human health.

Energy Efficiency

Electric motors are highly energy-efficient; they convert over 90% of the energy supplied to them into motion, which makes them an ideal choice for electric vehicles. This efficiency not only translates into reduced operating costs but also extends the battery life of an electric vehicle, increasing its overall range.

Regenerative Braking

Regenerative braking is a process that electric vehicles use to recover energy when they decelerate or come to a stop. It works by converting the kinetic energy of the vehicle into electrical energy, which is then stored in the battery pack. This process can significantly extend the range of an electric vehicle and reduces the wear and tear on the brake pads and rotors, resulting in lower maintenance costs.

Quiet Operation

Electric motors are virtually silent when they operate, making them an excellent option for electric vehicles that must comply with noise pollution regulations. Electric vehicles produce almost no noise pollution, which contributes to a more pleasant and peaceful driving experience.

High-Performance

Efficient electric motors are also capable of producing high levels of torque and power, allowing them to match or exceed the performance of traditional internal combustion engines. High-performance electric motors are particularly well-suited for sports cars and other high-speed vehicles that require instant acceleration and high power output.

The benefits of electric motors make them an increasingly attractive option for automotive manufacturers. As technology continues to advance, it is likely that electric motors will become even more efficient and cost-effective, driving further innovation in the automotive industry.

Overcoming Challenges: Scaling Up Electric Motors

While the benefits of high-power electric motors for vehicles are clear, their production presents significant challenges. Scaling up electric motors to deliver 500 horsepower requires advanced materials, precision engineering, and innovative design solutions.

One of the main challenges in scaling up electric motors is managing the heat generated by the high current flow. As power output increases, so does heat output, which can cause wear and tear on components and reduce efficiency. To overcome this challenge, engineers use advanced materials and cooling technologies to dissipate heat and maintain optimal operating conditions.

Another obstacle in producing high-power electric motors is managing the weight and size of the motor. As power output increases, so does the size and weight of the motor, which can limit its suitability for certain applications. Engineers address this challenge by using lightweight materials and optimizing the motor's design for maximum efficiency.

Advanced Materials for High-Power Electric Motors

The materials used in high-power electric motors are critical to their performance and efficiency. By using advanced materials, such as high-strength alloys, ceramics, and composites, engineers can reduce weight and increase durability. Additionally, these materials can withstand the high temperatures and pressures generated by high-power electric motors.

For example, some high-power electric motors use rare-earth magnets, which are made from a combination of neodymium, iron, and boron. These magnets are incredibly strong and can withstand high temperatures, making them ideal for use in electric motors with high power output. However, sourcing rare-earth metals can be challenging, and their production can be environmentally damaging.

Engineering Solutions for High-Power Electric Motors

In addition to advanced materials, engineers use innovative design solutions to produce high-power electric motors. This includes optimizing the motor's winding patterns and using advanced control systems to manage power output and reduce energy loss.

One engineering solution is the use of multiple smaller motors instead of a single large motor. By using several smaller motors, engineers can distribute power more efficiently, reduce weight and size, and increase reliability. This solution is commonly used in electric vehicles and hybrid vehicles, where space and weight are at a premium.

Overall, scaling up electric motors to deliver 500 horsepower requires a combination of advanced materials, precision engineering, and innovative design solutions. As technology continues to advance, it is likely that even more efficient and powerful electric motors will be developed, paving the way for a new era of high-performance electric vehicles.

The Future of High-Power Electric Motors

The future of high-power electric motors is brighter than ever. As the world transitions towards sustainable energy, the demand for efficient, high-performance electric vehicles is on the rise. Automobile manufacturers are investing heavily in the development of electric vehicles, and electric motors are at the heart of these efforts.

In recent years, technological advancements have enabled the production of high-power electric motors for vehicles. With power outputs of up to 500 horsepower, these motors are capable of propelling cars to incredible speeds while delivering unmatched efficiency.

As research and development efforts continue, the future prospects of high-power electric motors look even more promising. New materials, advanced manufacturing processes, and improved design techniques are being explored to further enhance the performance and efficiency of electric motors.

In addition, the use of electric motors in automotive applications is not limited to cars. Electric motors are being employed in a wide range of vehicles, including buses, trucks, and even airplanes. As battery technology improves and charging infrastructure expands, the potential applications for high-performance electric motors are limitless.

The benefits of using electric motors in automotive applications are numerous. They are highly efficient, produce minimal emissions, and provide instant torque, enabling impressive acceleration and performance. As the world continues to prioritize sustainability and environmental consciousness, the demand for these advantages will only continue to grow.

In conclusion, the future of high-power electric motors is a bright one. With ongoing research and development efforts, these motors will continue to revolutionize the automotive industry, delivering unprecedented performance and efficiency.

Conclusion: Unleashing the Potential of the 500 hp Electric Motor for Cars

In conclusion, the 500 hp electric motor for cars has the potential to transform the automotive industry. This high-power electric motor for vehicles is efficient and provides impressive performance, making it an ideal choice for high-speed electric vehicles.

Through the exploration of the inner workings of high-power electric motors, we have gained an understanding of the key components and technologies that contribute to their efficiency and performance. We have also explored the design and construction considerations for electric motors used in high-performance cars.

The power and torque provided by electric motors are the driving force behind their impressive acceleration and performance. With a high-power, high-torque electric motor, cars can achieve speeds of up to 200 miles per hour.

The use of electric motors in sports cars has revolutionized the driving experience, providing enhanced performance while reducing emissions. The numerous advantages of using electric motors in automotive applications, including energy efficiency and potential for regenerative braking, make them a promising choice for the future of high-performance, efficient electric vehicles.

While challenges remain in scaling up electric motors to deliver 500 horsepower, ongoing research and development efforts are focused on enhancing their performance, efficiency, and suitability for diverse automotive applications.

In summary, the 500 hp electric motor for cars has the potential to unleash power and efficiency in the automotive industry. As researchers and engineers continue to make advancements in this technology, we can look forward to even more impressive and efficient electric vehicles in the future.

.jpg)